Introduction

In the competitive landscape of American industrial and specialty chemical sourcing, a supplier's reputation is its most valuable currency. For procurement managers, plant operators, and R&D specialists seeking consistent, high-quality materials like sodium bicarbonate, reputation is not built on marketing alone. It is forged in the crucible of production technology. The methods, machinery, and quality control systems a supplier employs directly translate into the purity, consistency, and reliability of the product delivered. This article delves into the intricate relationship between advanced production technology and supplier reputation, with a focused lens on the sodium bicarbonate market. We will explore how technological investment by leading suppliers, such as those accessible through platforms like Chemtradeasia.com, creates a ripple effect of trust, risk mitigation, and long-term partnership value for American businesses.

The American market, with its stringent regulations from the FDA, FCC, and USP for various grades of sodium bicarbonate, demands nothing short of excellence. Whether for food processing, pharmaceutical formulation, flue gas desulfurization, or water treatment, inconsistencies in product quality can lead to catastrophic production delays, failed compliance audits, and compromised end-products. Consequently, buyers are increasingly looking beyond price sheets to audit a supplier's technological capabilities. The reputation of being a "technologically advanced supplier" is now a key differentiator, signaling a commitment to precision, innovation, and supply chain security that resonates deeply in today's risk-aware industrial environment.

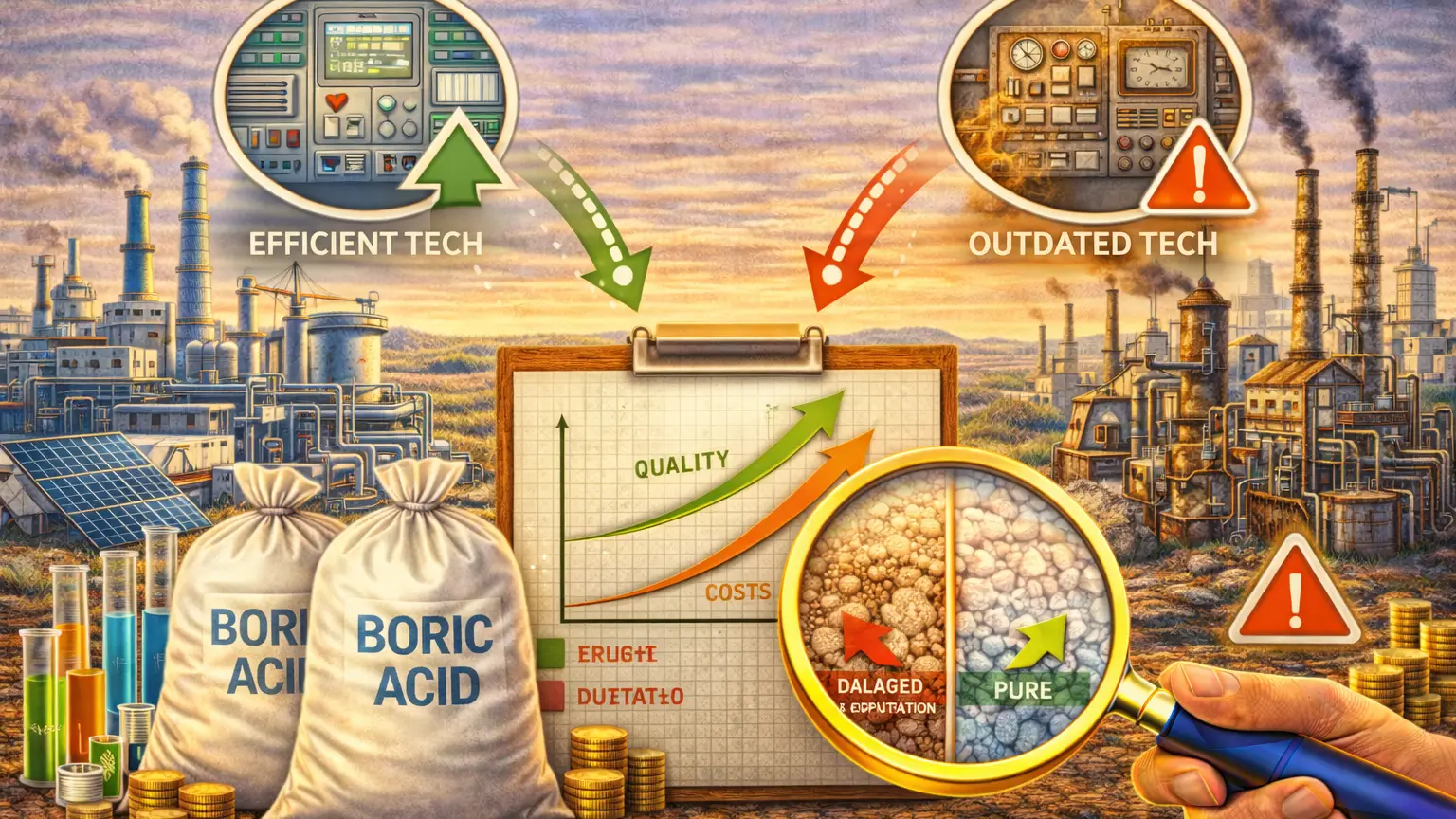

The Direct Link Between Technology and Perceived Value

The perceived value of a chemical supplier extends far beyond the cost per kilogram. It encompasses assurance, reliability, and the confidence that every batch will perform identically. Advanced production technology is the primary engine that drives this perception. When a supplier utilizes state-of-the-art Solvay process refinements or sophisticated carbonation reactors, it communicates a foundational commitment to quality. This technological backbone minimizes human error, maximizes process efficiency, and ensures that critical parameters—such as particle size distribution, bulk density, and purity levels—are held within exceptionally tight tolerances. For an American manufacturer using sodium bicarbonate as a leavening agent, a buffering agent, or a fire suppressant, this consistency is priceless.

Furthermore, technology enhances traceability and documentation, which are cornerstones of reputation in regulated industries. Modern Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) integrations allow suppliers to provide detailed certificates of analysis (CoA) that are digitally linked to specific production lots. This level of transparency, enabled by technology, transforms a supplier from a simple vendor into a validated partner. A platform like Chemtradeasia.com facilitates this connection by vetting suppliers who prioritize such technological investments, thereby aggregating a reputation for quality that individual buyers can leverage. The supplier's technological capability becomes a tangible, reportable asset that directly elevates its market standing.

Key Production Technologies Defining Modern Sodium Bicarbonate Manufacturing

The production of high-grade sodium bicarbonate has evolved significantly from basic methods. Leading suppliers differentiate themselves through several key technological applications. First is the refinement of the carbonation process. Advanced reactor designs with precise temperature, pressure, and concentration controls allow for the production of crystals with specific morphologies. This is crucial for applications where dissolution rate or flowability is important, such as in pharmaceutical tablet manufacturing or dry chemical fire extinguishers. Technology here directly dictates product performance.

Second, drying and milling technology plays a pivotal role. Fluidized bed dryers and precision air-classifying mills enable the production of consistent, free-flowing powders with controlled particle sizes—from fine powder to granular grades. For the food industry, a consistent fine grain ensures even reaction in baked goods. For industrial abrasives, a specific granular size is critical. Third, and perhaps most importantly, is integrated quality control technology. In-line Near-Infrared (NIR) spectroscopy, laser diffraction particle size analyzers, and automated titration systems provide real-time data, allowing for immediate process adjustments. This shift from post-production testing to in-process quality assurance is a hallmark of a top-tier supplier and a massive reputational booster, as it virtually eliminates the risk of off-spec product leaving the facility.

Case in Point: Sodium Bicarbonate Specifications and Quality Benchmarks

To understand the practical impact of technology, one must examine the exacting specifications of sodium bicarbonate. A reputable supplier doesn't just meet these standards; it consistently exceeds them with minimal batch-to-batch variance. Key specifications include purity (often >99.5% for USP/FCC grades), heavy metal content (like lead and arsenic at parts-per-million levels), and loss on drying (moisture content). Advanced filtration and purification technologies, such as membrane filtration and ion exchange, are essential to achieve and maintain these ultra-high purity levels, directly impacting a supplier's reputation for serving sensitive markets like pharmaceuticals and food.

Another critical benchmark is particle size distribution (PSD). A supplier using outdated milling technology may produce a batch with a wide PSD, leading to segregation in transport and inconsistent performance. In contrast, a supplier with modern, computerized milling and air classification can guarantee a specific PSD (e.g., 90% of particles between 50 and 150 microns). This precision is vital. In flue gas cleaning, specific particle size affects reactivity and flow in injection systems. In personal care products, it affects the feel and efficacy of exfoliants. The ability to reliably produce and certify to these precise physical specifications, enabled by sophisticated technology, is what separates a commodity supplier from a trusted technical partner. Suppliers featured on global platforms like Chemtradeasia.com are often selected for their demonstrated capability to meet these rigorous, application-specific benchmarks.

How Technological Prowess Mitigates Supply Chain Risks

In the post-pandemic era, American businesses prioritize supply chain resilience above all else. A supplier's production technology is a direct indicator of its risk profile. Automated, technologically advanced plants are less susceptible to labor shortages and can maintain continuous, 24/7 production cycles, ensuring steady supply. Moreover, technology enables scalability and flexibility. A supplier with modular reactor systems can more quickly ramp up production of a specific grade of sodium bicarbonate in response to market demand—a significant advantage during sudden shortages or for just-in-time manufacturing clients.

Technology also mitigates quality-related risks. Real-time monitoring and automated control systems prevent costly production errors that could lead to a full batch rejection. For the buyer, this means no unexpected quality audits, no production line stoppages waiting for replacement materials, and no risk of contaminating their own processes. The reputational benefit for the supplier is immense: they become known as a "zero-defect" or "high-reliability" source. This reputation for risk mitigation, built on a visible technological foundation, allows suppliers to command loyalty and potentially a price premium, as they are seen as an insurance policy against downstream operational disruptions.

Building Long-Term Partnerships Through Technological Transparency

The ultimate testament to a supplier's reputation is the formation of long-term, strategic partnerships. Technology fosters this by enabling unprecedented transparency and collaboration. Suppliers who offer virtual plant tours, share process flow diagrams, and provide detailed, data-rich CoAs are building trust through transparency. They are inviting customers to see the technological rigor behind the product. This openness is particularly valued by American companies with strong ethical sourcing and ESG (Environmental, Social, and Governance) commitments.

Furthermore, a supplier's investment in R&D technology signals a commitment to the future. For instance, a supplier developing more energy-efficient production methods for sodium bicarbonate or exploring new, high-purity grades for emerging battery technology applications is investing in the future needs of its partners. This forward-looking technological posture transforms the buyer-supplier relationship from transactional to collaborative. Platforms that connect global suppliers with local markets, such as Chemtradeasia.com, amplify this by facilitating communication around technological capabilities and innovation roadmaps. When a buyer knows their supplier is continuously evolving and improving its technology, it creates a powerful incentive for a lasting partnership, securing the supplier's reputation as an industry leader rather than just a source of material.

Conclusion

The reputation of a chemical supplier in the American market is inextricably linked to its mastery of production technology. For critical commodities like sodium bicarbonate, where specifications are tight and applications are diverse, technology is the non-negotiable foundation of quality, consistency, and reliability. From precision carbonation and milling to integrated quality assurance and supply chain scalability, every technological advancement directly contributes to a supplier's perceived value and trustworthiness. This technological edge mitigates risk for buyers and paves the way for deep, strategic partnerships.

For American businesses seeking to secure their supply chains with reputable partners, the imperative is clear: evaluate the technology behind the product. Engaging with suppliers who demonstrate a clear commitment to advanced manufacturing processes—whether directly or through curated platforms like Chemtradeasia.com—is a strategic decision that protects operations, ensures compliance, and drives long-term success. In the final analysis, a supplier's reputation is not merely claimed; it is manufactured, batch by batch, through the sophisticated technology it employs.

Leave a Comment