Introduction

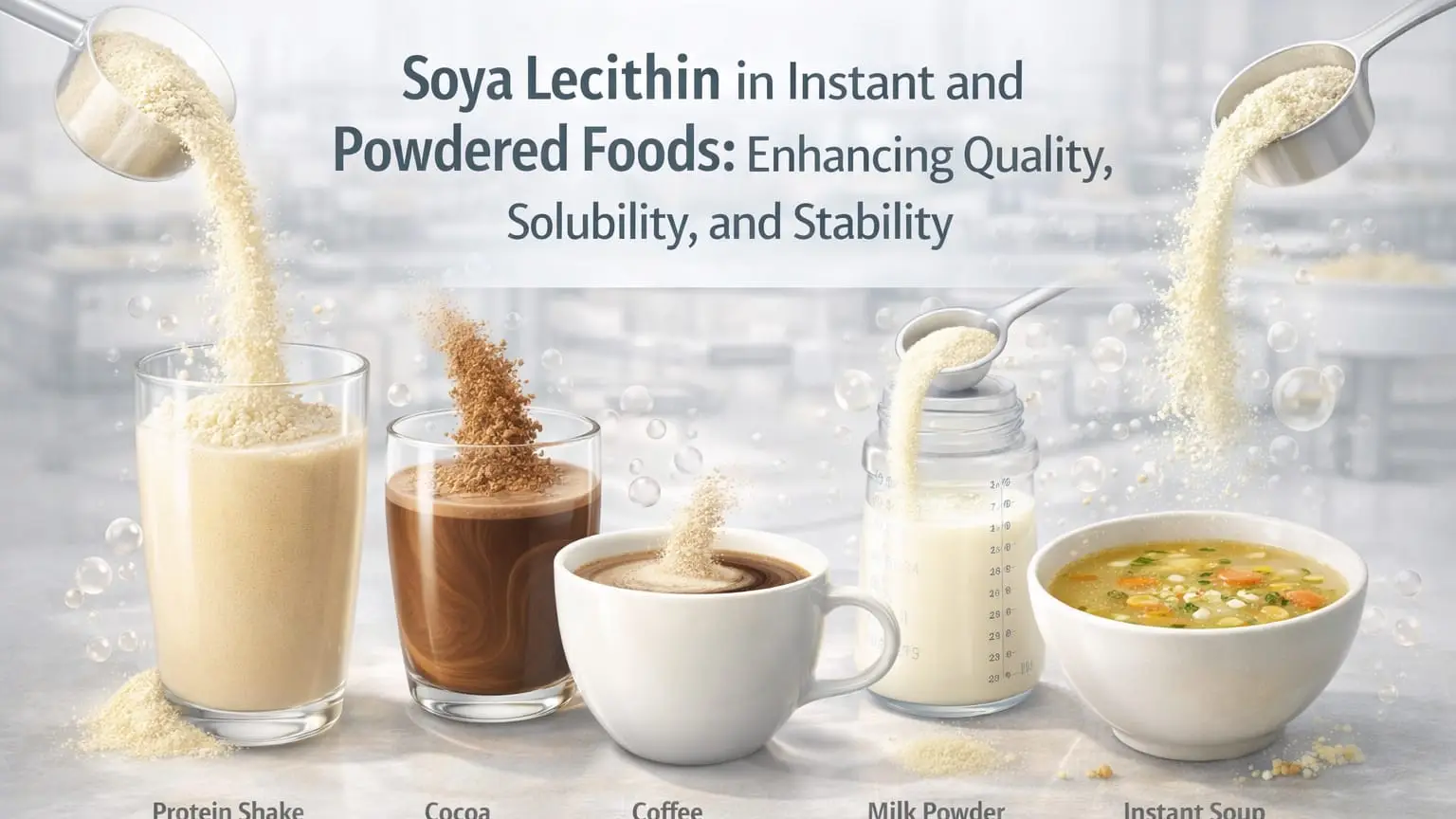

The demand for convenient, ready-to-use foods has reached new heights, driven by busy lifestyles, urbanization, and the need for quick nutrition. Within this market, instant and powdered products from soups, sauces, and dairy powders to protein shakes and infant formulas are dominating. A key ingredient ensuring these products perform consistently is soya lecithin.

Soya lecithin, a natural phospholipid complex derived from soybeans, acts as an emulsifier, dispersant, and processing aid. Its unique molecular structure, combining water-attracting and fat-attracting regions, allows it to stabilize oil-water mixtures, prevent separation, improve powder wettability, and enhance flow properties. These functions are critical for instant and powdered foods, ensuring smooth reconstitution, uniform texture, and even nutrient distribution.

Understanding Soya Lecithin

Soya lecithin is produced as a by-product of soybean oil refining. It is primarily composed of phospholipids such as phosphatidylcholine, phosphatidylethanolamine, and phosphatidylinositol, along with minor components including triglycerides and sterols. During the degumming process, water hydrates phospholipids, which are then separated via centrifugation.

Lecithin can be processed into different forms such as liquid, powdered, or granular, each optimized for specific applications. For instant and powdered foods, powdered lecithin is preferred. It can be spray-dried or de-oiled to increase phospholipid concentration, enabling it to blend seamlessly with dry ingredients and ensuring consistent functionality upon reconstitution.

Its plant-based origin makes it suitable for clean-label applications, replacing synthetic emulsifiers while appealing to health-conscious consumers.

Key Functional Benefits in Instant and Powdered Foods

Soya lecithin provides multiple critical benefits in powdered and instant food systems:

1. Emulsification and Stabilization

Lecithin stabilizes oil-in-water systems, keeping fats and oils evenly distributed. This prevents separation in instant beverages, soups, sauces, and dessert mixes, creating smooth textures and consistent mouthfeel.

2. Dispersibility and Wettability

By coating hydrophobic particles, lecithin reduces surface tension, allowing powders to reconstitute quickly without clumping. This improves solubility and accelerates mixing, which is essential for protein shakes, meal replacements, and instant beverages.

3. Flowability and Anti-Caking

Lecithin improves powder flow during manufacturing, filling, and packaging. It acts as a mild anti-caking agent, minimizing lumps and ensuring consistent dosing, which is critical for automated production lines and quality control.

4. Nutrient and Flavor Protection

Lecithin protects fat-soluble vitamins (A, D, E, K) and natural colors from oxidation, maintaining nutritional content and visual appeal. Its multifunctionality can reduce the need for additional additives, supporting clean-label formulation strategies.

Applications Across Instant and Powdered Food Products

Soya lecithin is widely used across multiple instant and powdered food categories:

- Instant Beverages: Coffee, cocoa, and nutritional drinks rely on lecithin for smooth dispersion, preventing fat separation and ensuring even flavor release.

- Powdered Dairy Products: Milk powders, creamers, and plant-based alternatives benefit from improved protein stability, controlled agglomeration, and enhanced texture. Typical usage ranges from 0.2–1%.

- Instant Soups and Sauces: Lecithin ensures uniform fat, spice, and flavor distribution, enabling rapid reconstitution and consistent taste.

- Sports Nutrition and Clinical Nutrition: Protein powders, meal replacements, and infant formulas utilize lecithin for mixability, palatability, and nutrient delivery.

Across all applications, lecithin improves production efficiency by reducing dust, shortening mixing times, and ensuring smooth powder handling.

Selecting the Right Lecithin Form

Soya lecithin is available in three main forms, each offering distinct advantages:

- Fluid (Liquid) Lecithin: Ideal for oil-based, high-volume operations. Easy to pump and blend, but may introduce flavor or moisture.

- De-Oiled Powder: High phospholipid content, neutral flavor, and precise dosing. Suitable for dry blends, instant solubility, and applications where taste neutrality is critical.

- Granules: Agglomerated powder designed for reduced dust, improved handling, and controlled dissolution. Best for consumer-facing products and specialty applications.

Choosing the correct form depends on product formulation, equipment compatibility, regulatory compliance, and total cost-in-use.

Sourcing and Supply Chain: Partnering with Trusted Suppliers

Consistent performance relies on sourcing high-quality lecithin. Platforms such as Chemtradeasia connect manufacturers with verified suppliers offering:

- Technical data sheets (TDS) and material safety data sheets (MSDS)

- Various forms and specifications of lecithin

- Compliance with international food safety standards

- Guidance on application, dosing, and optimization

Working with reliable suppliers reduces risks of inconsistent quality, production delays, or regulatory non-compliance, ensuring lecithin performs reliably in industrial-scale applications.

Conclusion

Soya lecithin is a foundational ingredient in instant and powdered foods, enabling emulsification, dispersibility, and stability. Its multifunctional properties enhance product texture, solubility, nutrient protection, and processing efficiency, while supporting clean-label and plant-based trends.

Investing in high-quality lecithin powder and sourcing it through trusted suppliers is a strategic imperative for manufacturers. By integrating this versatile natural emulsifier, brands can deliver convenient, palatable, and nutritionally consistent products, maintaining a competitive edge in an increasingly dynamic global food market.

Leave a Comment