Introduction

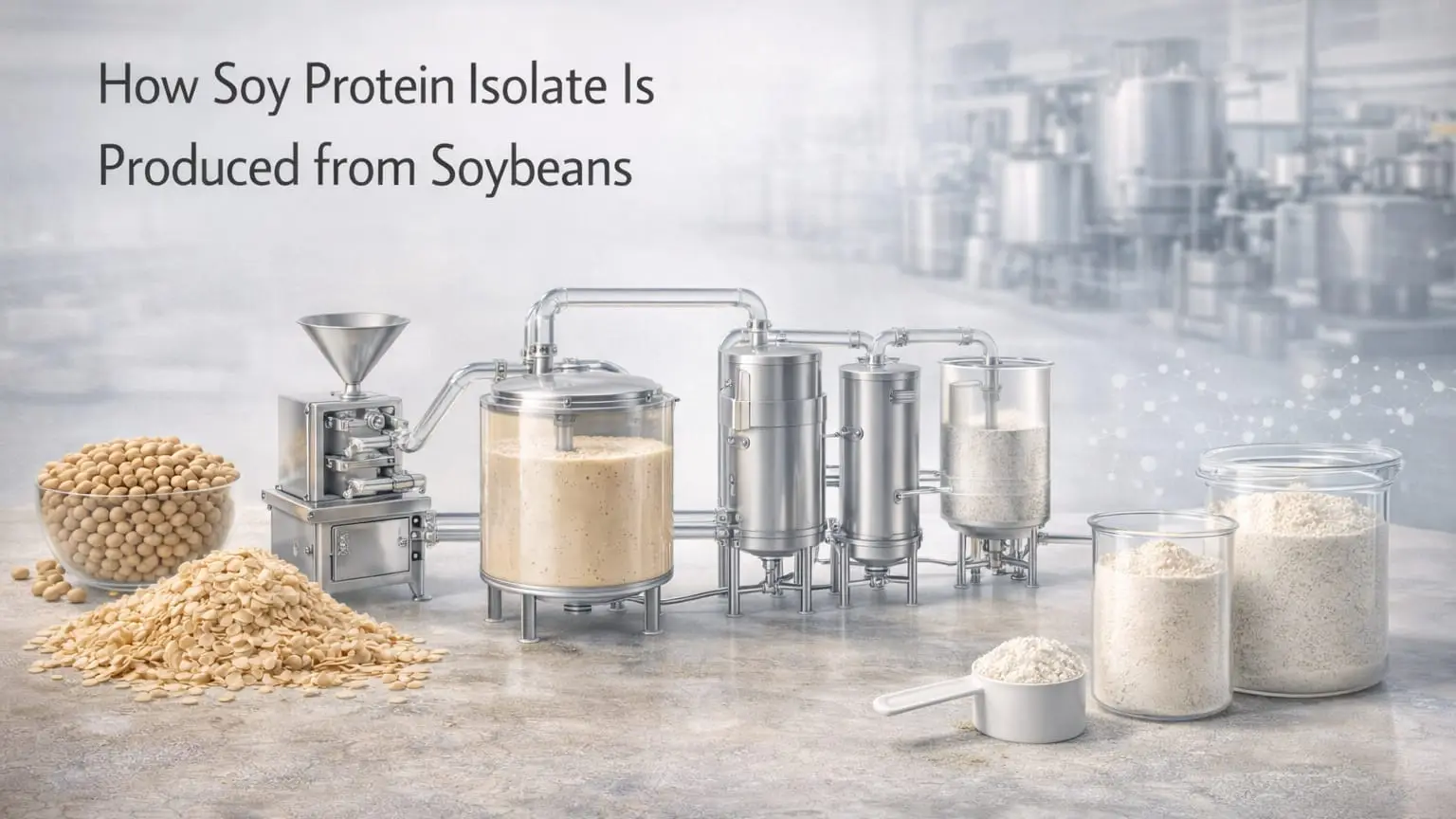

Soy protein isolate production converts whole soybeans into a high-purity plant protein used across food, beverage, and nutrition industries. As demand for plant-based and high-protein products continues to grow, manufacturers rely on soy protein isolate for its consistent quality, functional performance, and nutritional value. Understanding how soy protein isolate is made helps ingredient buyers, formulation scientists, and R&D teams evaluate quality, sourcing, and application suitability.

Soybeans remain the preferred raw material for protein isolation due to their naturally high protein content and well-established global processing infrastructure. Through a controlled extraction and purification process, soy protein isolate achieves protein concentrations exceeding 90 percent, making it one of the most refined plant proteins available.

Soybeans as the Raw Material

The production process begins with carefully selected soybeans, typically containing between 40 and 45 percent protein. Raw material quality directly influences the final protein isolate. Processors prioritize soybeans with low moisture content, minimal damage, and low levels of foreign matter to reduce contamination risk and processing losses.

Before protein extraction begins, soybeans undergo preliminary handling steps designed to prepare them for efficient isolation. These steps focus on cleaning, dehulling, and defatting, which together create a stable and uniform base material for protein extraction.

Cleaning, Dehulling, and Defatting

Incoming soybeans are first cleaned to remove dust, stones, and other foreign materials. Mechanical dehulling follows, separating the hulls from the cotyledons. Removing the hulls improves protein yield and reduces fiber content in the final product.

The dehulled soybeans are then flaked and defatted using food-grade solvent extraction, most commonly with hexane. This step removes soybean oil and reduces fat content to below one percent. The resulting defatted soy flakes serve as the primary raw material for soy protein isolate manufacturing. The extracted oil is recovered as a valuable co-product, contributing to process efficiency and waste reduction.

Protein Extraction and Solubilization

Defatted soy flakes are mixed with water under controlled alkaline conditions, typically at a pH between 8 and 9. This environment solubilizes the soy proteins while leaving insoluble carbohydrates and fiber behind.

The slurry undergoes centrifugation or filtration to separate the soluble protein fraction from insoluble residues. This separation step plays a critical role in determining protein purity and functional quality. Precise control of temperature, pH, and residence time helps preserve protein structure and solubility.

Protein Precipitation and Washing

The extracted protein solution is then adjusted to its isoelectric point, usually around pH 4.5. At this pH, soy proteins lose solubility and precipitate into a curd. This isoelectric precipitation step is central to achieving high protein concentration in soy protein isolate.

The protein curd is collected and washed multiple times with water. Washing removes residual sugars, minerals, and other non-protein components, further increasing purity. Effective washing also reduces off-flavors and improves the sensory profile of the final ingredient.

Neutralization and Drying

After washing, the protein curd is neutralized by adjusting the pH back to near neutral. Neutralization stabilizes the protein and restores functional properties such as solubility and emulsification.

The neutralized protein slurry is pasteurized to ensure food safety and then spray dried to produce a fine, free-flowing powder. Spray drying parameters influence particle size, bulk density, and dispersibility, all of which affect downstream processing performance. The result is a food-grade soy protein isolate suitable for a wide range of applications.

Quality Control During Production

Quality control is integrated throughout soy protein isolate production. Manufacturers monitor protein content, targeting levels above 90 percent on a dry basis. Functional properties such as solubility, water absorption, emulsification, and viscosity are routinely tested to ensure consistent performance.

Microbiological testing confirms compliance with food safety standards, including HACCP and relevant national regulations. Moisture content is typically controlled below 7 percent to prevent microbial growth and maintain shelf stability. Additional checks may include testing for residual solvents, heavy metals, and allergen compliance.

Conclusion

Soy protein isolate production transforms soybeans into a high-purity, functional protein ingredient through controlled extraction, precipitation, and drying. Each stage of the process contributes to protein quality, safety, and performance, making manufacturing precision essential for reliable outcomes.

For ingredient buyers and R&D teams, understanding how soy protein isolate is produced supports informed sourcing decisions and successful product development. Consistent processing and robust quality control ensure that soy protein isolate remains a cornerstone ingredient for modern plant-based and high-protein formulations.

Leave a Comment