Introduction

In the complex landscape of American industrial manufacturing, procurement decisions carry significant weight, directly impacting product quality, operational efficiency, and bottom-line profitability. For a versatile and critical compound like boric acid, sourcing is not merely a transactional purchase but a strategic decision with far-reaching consequences. Used across sectors from agriculture and ceramics to pharmaceuticals and nuclear power, the performance of boric acid is intrinsically linked to its quality and consistency. Unfortunately, many businesses fall prey to common, yet avoidable, sourcing mistakes that compromise the efficacy of this essential chemical.

This article delves into the most prevalent sourcing errors that American companies make and how these missteps directly degrade boric acid performance. More importantly, it provides a roadmap for navigating the procurement process successfully, emphasizing the value of partnering with established, quality-focused suppliers. By understanding these pitfalls, procurement managers, plant operators, and R&D professionals can make informed decisions that safeguard their processes, products, and reputation.

The Critical Role of Boric Acid in American Industries

Boric acid's utility stems from its unique chemical properties, acting as a flame retardant, a mild antiseptic, a neutron absorber, a fluxing agent, and a precursor to other boron compounds. In the United States, its applications are vast and vital. The agriculture industry relies on it as a micronutrient in fertilizers and a key ingredient in pesticides. The glass and ceramics sector, a cornerstone of American manufacturing, uses it to improve thermal shock resistance and durability in fiberglass, borosilicate glass, and ceramic glazes. Furthermore, the pharmaceutical industry depends on high-purity Boric Acid USP Grade for medicinal formulations, while wood treatment plants utilize it for its preservative qualities against rot and insects.

The performance demands in each of these applications are stringent and non-negotiable. For instance, trace impurities in boric acid used for fiberglass production can lead to defects, weakened strands, and production line failures. In pharmaceutical applications, any deviation from the strict USP (United States Pharmacopeia) standards can render a batch unusable, causing massive financial loss and regulatory complications. Therefore, sourcing is the first and most critical line of defense in ensuring that the boric acid performs its intended function flawlessly within complex industrial ecosystems.

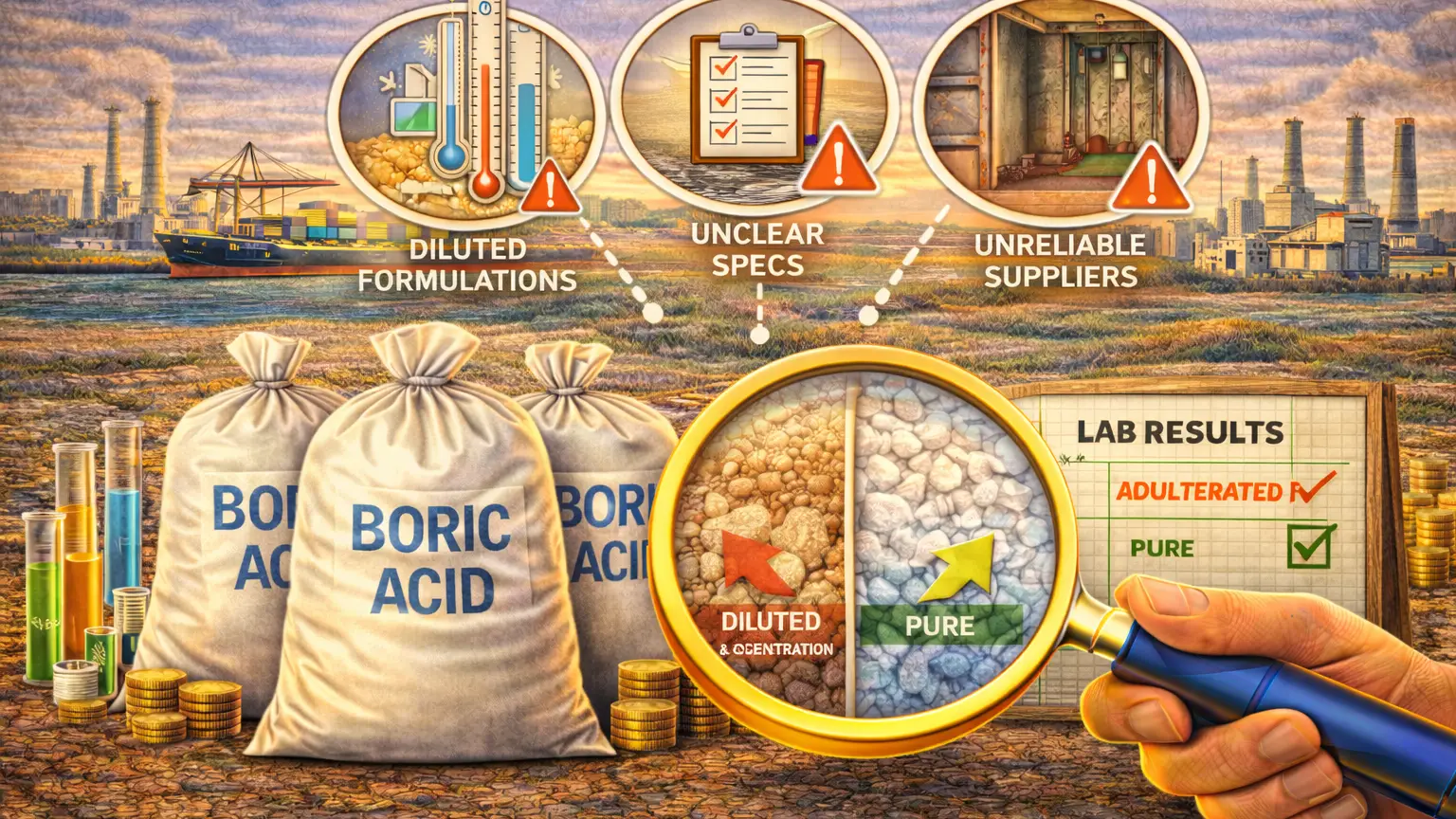

Mistake #1: Prioritizing Price Over Purity and Specification

The most seductive and damaging mistake in chemical sourcing is making price the primary decision-making factor. While cost control is essential, selecting boric acid based solely on the lowest bid often leads to acquiring substandard material. Inferior boric acid may contain elevated levels of contaminants like sulfates, chlorides, or heavy metals. These impurities can catalyze unwanted reactions, cause corrosion in processing equipment, introduce defects in final products, or fail to meet regulatory standards for consumer goods.

The real cost of cheap boric acid is rarely the invoice price. It manifests as production downtime due to clogged nozzles or off-spec batches, increased waste and rework, damaged customer relationships due to poor product quality, and potential liability from non-compliance. A reputable supplier like Chemtradeasia.com provides detailed Certificates of Analysis (CoA) for each batch, guaranteeing that the boric acid quality meets the agreed-upon specifications. Investing in certified purity from a trusted partner is an investment in operational stability and brand integrity, far outweighing the minimal upfront savings from a cut-rate source.

Mistake #2: Overlooking Supplier Verification and Reliability

Another critical error is failing to conduct thorough due diligence on a boric acid supplier. In today's global market, a website and a price list are not sufficient indicators of reliability. Companies must verify a supplier's credentials, manufacturing capabilities, quality control protocols, and industry reputation. A supplier's longevity, client portfolio, and adherence to international standards (like ISO certifications) are strong indicators of their commitment to consistency and service.

An unreliable supplier poses multiple risks: inconsistent quality between shipments, inability to scale with your demand, poor communication during disruptions, and lack of technical support. Partnering with an established global supplier such as Chemtradeasia.com mitigates these risks. They offer not just a product, but a dependable supply chain, expert knowledge on boric acid applications, and a proven track record of serving the American market with consistent, high-grade material. This reliability is crucial for maintaining just-in-time inventory systems and uninterrupted production schedules.

Mistake #3: Ignoring the Importance of Proper Grade Selection

Boric acid is not a one-size-fits-all commodity. Using the incorrect grade for an application is a direct path to performance failure. The two primary classifications are Technical Grade and USP Grade. Technical grade boric acid is suitable for industrial applications like glass manufacturing, flame retardants, and metallurgy, where high purity is important but pharmacopeia standards are not required. Boric Acid USP Grade, however, is manufactured and tested to meet the rigorous purity and safety standards of the United States Pharmacopeia, making it mandatory for food, cosmetic, and pharmaceutical uses.

Selecting a technical grade for a pharmaceutical application would be a catastrophic regulatory failure. Conversely, using expensive USP grade in an industrial enamel process is an unnecessary cost. A proficient supplier provides clear guidance on grade specifications. For example, Chemtradeasia.com offers distinct product lines with transparent specifications. Their technical grade ensures optimal performance in industrial settings, while their USP grade provides the documentation and purity needed for sensitive applications. Understanding and specifying the correct grade—assisted by a knowledgeable supplier—is fundamental to achieving desired outcomes and maintaining compliance.

Mistake #4: Neglecting Logistics and Supply Chain Resilience

The final common mistake is treating logistics as an afterthought. Even the highest quality boric acid can be compromised by poor handling, unsuitable packaging, or unreliable delivery. Boric acid is hygroscopic, meaning it absorbs moisture from the air. If shipped in inadequate packaging or stored improperly, it can form lumps or hard cakes, making it difficult to handle and measure accurately, thus affecting dosage and performance in precise formulations.

Furthermore, an fragile or geographically concentrated supply chain leaves a business vulnerable to disruptions, as seen during recent global logistics crises. A robust supplier partners with reliable freight forwarders and offers packaging options (such as moisture-resistant bags or sealed drums) suited to the product's nature and the client's storage conditions. They also provide supply chain transparency and have the logistical network to ensure on-time delivery. A partner like Chemtradeasia.com leverages its global distribution expertise to navigate these complexities, ensuring that the boric acid arrives at your American facility in the same condition it left the factory, ready to perform as expected.

Conclusion

Sourcing boric acid effectively requires a strategic perspective that looks beyond the price tag. The common mistakes of prioritizing cost over quality, neglecting supplier vetting, misunderstanding grade requirements, and underestimating logistics all converge to undermine the very performance that the chemical was purchased to deliver. In the competitive American industrial arena, these errors translate into tangible losses—compromised product quality, operational inefficiencies, and eroded profit margins.

The solution lies in informed, partnership-based procurement. By prioritizing certified purity, verifying supplier reliability, meticulously selecting the appropriate grade, and securing a resilient supply chain, businesses can fully leverage the functional benefits of boric acid. Partnering with a dedicated and experienced global supplier such as Chemtradeasia.com provides access to high-quality Boric Acid USP and Technical Grades, expert guidance, and dependable logistics. This approach transforms boric acid from a mere input into a reliable catalyst for quality, innovation, and sustainable growth across countless American industries.

Leave a Comment