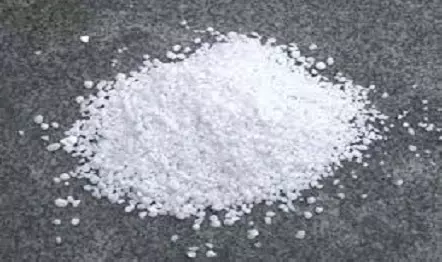

Copper Sulphate Anhydrous

|

IUPAC Name |

: Copper Sulphate |

|

Cas Number |

: 7758-98-7 |

|

HS Code |

: 2833.25.00 |

|

Formula |

: CuSO4 |

Basic Info

|

Appearance Name |

: Powder Light Grey |

|

Common Names |

: Copper Monosulfate, Cupric Sulfate, Cupric Sulfate Anhydrous, Sulfuric Acid |

|

Packaging |

: 25 kg PP Bag |

---china.webp)

English

English

Indonesian

Indonesian

简体字

简体字

العربية

العربية

Español

Español

Français

Français

Português

Português

日本語

日本語

한국어

한국어

Tiếng Việt

Tiếng Việt